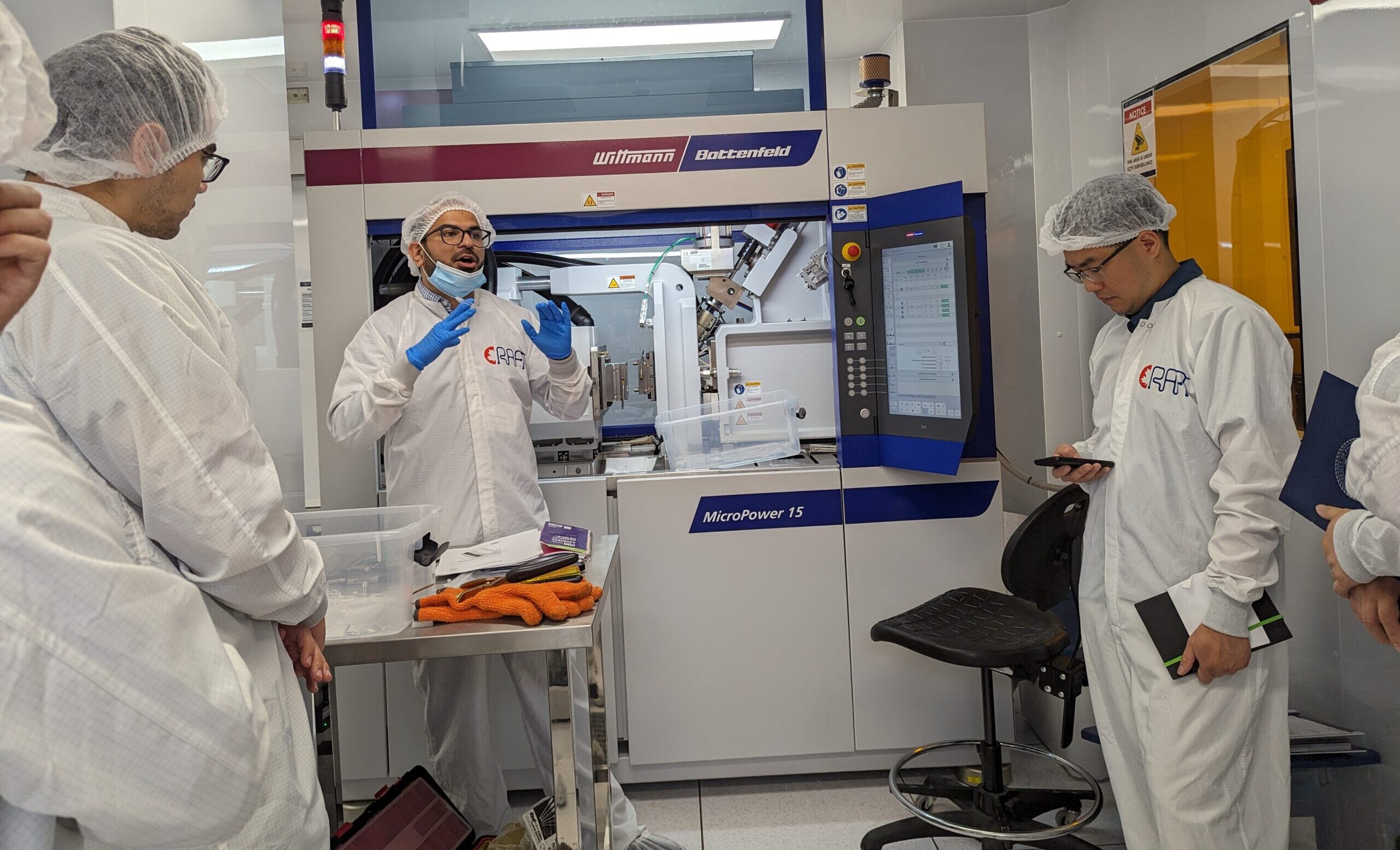

Sathishkumar Narayanasamy (left), a postdoctoral fellow in Prof. Aaron Wheeler’s lab, answers participants’ questions about the roll-to-roll polymer coater for the rapid manufacture of tens of thousands of diagnostic microfluidic devices.

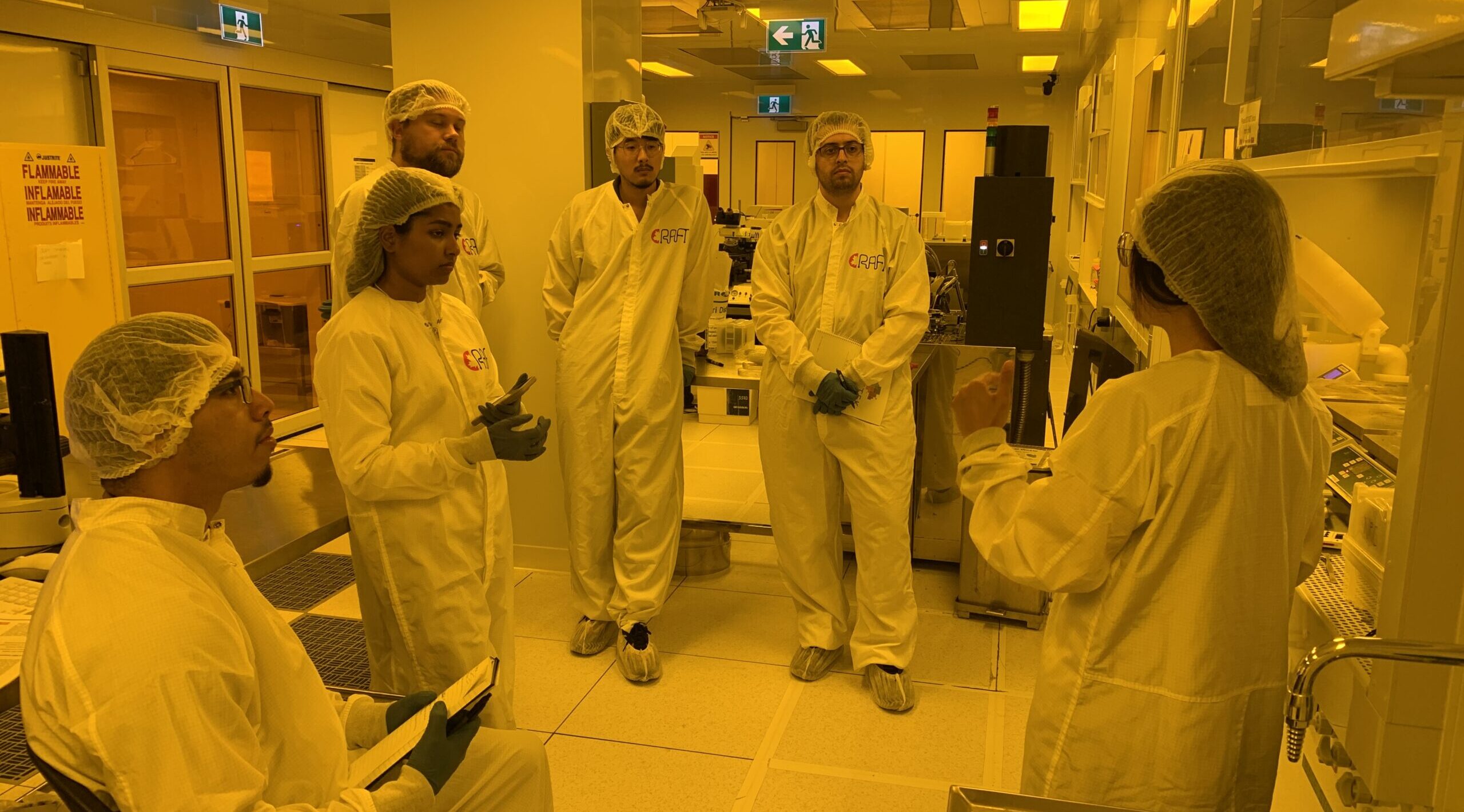

CRAFT hosts its 2023 hands-on crash course in microfluidics.

Two weeks ago, CRAFT held its three-day Microfluidics Professional Course at the University of Toronto (UofT). This year’s installment was attended by 26 participants from various universities—including UBC, Ottawa and McMaster—hospitals, companies and the National Research Council of Canada (NRC).

The course was designed by CRAFT’s Operations Manager Dr. Dan Voicu and NRC Technical Officers Kayla Soon, Abdul Wasay, and Victor Sit to provide non-experts— such as clinicians, biologists, and industry researchers— with a quick and intense introduction to the science and technology of microfluidics. These Technical Officers spend 50% of their time overseeing CRAFT facilities at UofT, training students to use the equipment and helping students troubleshoot their research projects.

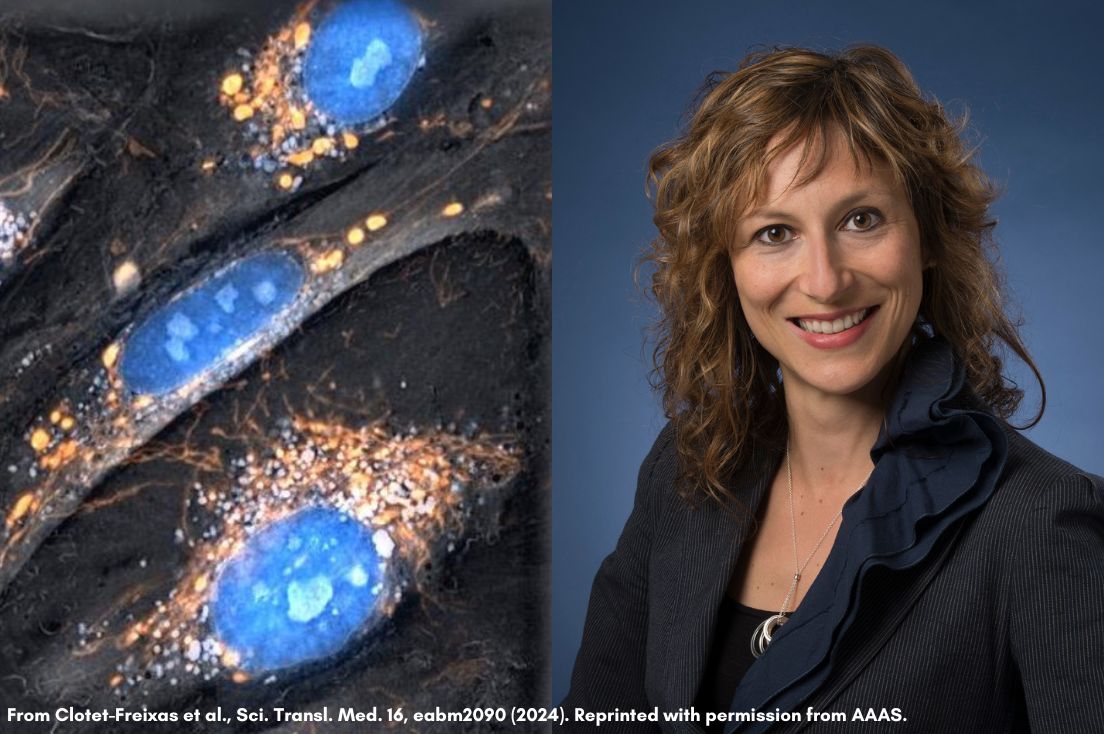

In the mornings, course participants attended lectures that introduced them to the theoretical underpinnings of microfluidics, the fabrication of microfluidic devices and examples of different applications of microfluidics such as disease modelling and carbon capture and conversion. These lectures were given by world-renowned UofT Professors Milica Radisic, David Sinton, Axel Guenther and Edmond Young, as well as Research Officers Drs. Keith Morton and Michael Dryden from NRC’s Medical Devices Research Centre.

Participants spent their afternoons in CRAFT’s nationally unique research facilities putting into practice some of the knowledge they learned in the morning lectures. In the CRAFT Device Foundry’s 250+ NASM of cleanrooms, Kayla taught participants how to use conventional and direct-write photolithography to make their own microfluidic devices which they kept as a memento after the course. Dan taught participants how to mold polydimethylsiloxane onto the freshly prepared silicon masters to fabricate their final devices. PhD candidates Kevin Perera and Jeremy Newton introduced participants to other common fabrication techniques including micro-milling and 3D printing. Abdul and postdoctoral fellow Sathishkumar Narayanasamy provided participants with demonstrations of two specialized instruments for high-volume device production (i.e, > 10,000 devices), namely the injection molder and roll-to-roll polymer coater.

In the CRAFT Tissue Foundry, Victor gave participants a demonstration of the facility’s newest addition: a highly integrated platform for automated, high-throughput imaging. The platform consists of an automated liquid handler, a robotic arm, an automated incubator, and a high-content confocal imaging system. This platform enables researchers to perform high-throughput studies, such as automated drug screens on 10+ human microtissue models at a time, which could significantly accelerate drug discovery and development efforts.

“We’ve been offering this course since 2014 to introduce non-expert researchers to the field of microfluidics and its vast potential to address a wide range of challenges in disparate fields. In light of the popularity of this summer’s course, we will be offering it again, with several key additions, in subsequent summers,” says Dan.

The Centre for Research and Applications in Fluidic Technologies (CRAFT) is a joint venture of UofT and NRC. It is an Institutional Strategic Initiative at UofT and is generously supported by the Faculties of Applied Science & Engineering, Arts & Science, Pharmacy and Medicine.

Dr. Keith Morton, a Senior Research Officer and Team Lead at NRC, delivering a lecture titled “Microfluidics: Merging liquids and microfabrication.”

NRC Technical Officer Kayla Soon in the CRAFT Device Foundry demonstrating various methods involved in the fabrication of microfluidic device prototypes.

UofT Professor Edmond Young delivering a lecture titled “Advances in organ-on-a-chip barriers and interfaces with floating hydrogels and matrix-derived membranes.”

NRC Technical Officer Abdul Wasay showing participants how to use the CRAFT Device Foundry’s injection molder for high- volume production of microfluidic devices.